Electric vehicles (EV) are the future of automobile industries and soon would be replacing fossil fuel driven traditional vehicle seen since beginning of automobile evolution. Fossil fuels are limited in nature and create lot of pollution which is a great threat to environment, this led to the need for search of alternate source for fuel to run the automobiles. #Electric vehicles looks better option in one way as they uses rechargeable batteries to run, but that's not the end of the problem. We need power source to charge these #EV batteries and that comes from our conventional electric power station some of which still uses fossil fuel, but yes some other uses hydro power, solar and wind power which are not going to cost much and doesn't create any environmental pollution. We should be more focused on hydro power plants, wind power plants and solar power plants to actually have Eco-friendly automobiles else this will lead to another new problem.

Again the batteries are made mostly from Lithium, which comes from nature and which is also not unlimited. Today fossil fuels have gone costly, tomorrow these batteries will become expensive as lithium reserve will keep depleting in nature. So, we would have to keep searching for alternate materials for reliable batteries or alternate source of energy.

Next comes the disposal of used and end of life batteries in environment friendly manner to minimize their impact on environmental pollution like soil pollution or water pollution etc., wherever they are disposed. We should look for proper disposal of used batteries or for recycling them. Today battery manufacturing industry is on demand tomorrow such recycling and e-waste industries will be in demand. Anyway these challenges and opportunities will come and go, that is part of business.

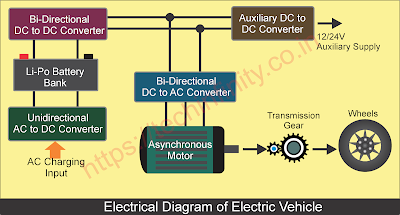

Let us see what are the electrical components of an electric vehicle. The major parts inside an EV is battery bank and an asynchronous AC induction motor. Some smaller vehicles do use DC motor also like electric scooters, but for bigger vehicles like car and buses uses induction motor as it is best suited for required mechanical power and efficiency. And then we have power electronic systems to drive motor and charge battery.

Let us see in detail each electrical component of an EV as listed below.

- Battery Bank

- Onboard Charger

- DC-DC Converter

- DC-AC Inverter

- Motor

- Auxiliary DC-DC Inverter

- Auxiliary Battery (not shown in image)

Battery Bank

There are many types of rechargeable cells available in market which when compared w.r.t weight, charge holding capacity, size, cost and charge discharge cycle. Among then Lithium Ion (Li-Ion) cells suits the best for electrical vehicles and hence are used today in EVs. It is our regular cylindrical Li-ion cell which are used in our old laptop batteries. New laptops uses flat shaped Li-Ion cells to reduce the thickness of device. These cylindrical li-ion cells are of 3.7V, 2500mAh or 2800mAh etc, when combined in serial and parallel combinations, can provide hundreds of volts and charge holding capacity in terms of tens or hundreds of ampere hour (Ah).

Electrical vehicles uses DC voltage in range from 200 to 800V DC. For achieving such high DC voltage 50 to 200 such small cells are to be connected in series and similar banks will have to be connected in parallel to get high "Ah" rating to hold more power so that vehicle runs longer per charge.

Based on the charge discharge cycle count capacity of these li-ion cells, vendor are in condition to give 5 yrs warranty on battery banks considering one charge and discharge cycle per day in a year. The battery banks have considerable weight inside an EV, hence a bed of such battery banks are laid in the bottom of EV, this gives lower center of gravity and since the banks are spread over base, it gives better stability to vehicle.

Such high number of cells in the battery bank operating at high voltage during charging and discharging cycle obviously will release heat. And to maintain their temperature liquid coolants are circulated between cell array which is then sent back to radiator at front with big cooling fan and then recirculated using a pump. These coolants are also used to maintain temperature of high voltage electronic sections inside the EV.

Onboard Charger:

Every EV has its inbuilt battery charger unit which takes AC input from our AC power outlet and converts it to required DC voltage to charge the battery bank. Such chargers are normally designed to do over night charging opposite to on road charging stations which charges faster on the go.

Its a very basic principal that faster we charge a battery the lesser is its life span and vice-e-versa. Same is applicable to discharging of batteries. This is because the change in chemical composition which happens inside battery during charging and discharging need certain amount of time to happen. If we try to charge faster, the terminal voltage across the battery may reach to full charge voltage quickly, but actually the chemical changes within each cell would not have completed fully. These onboard chargers are designed for slow charging.

These charger units are usually placed in front side of vehicles which can be identified with two input cables and two output cables. All high voltage cables inside EV are having specific color like "Orange". This charger is uni-directional, i.e. it only use to convert AC input to DC supply for charging but not the reverse process.

DC-DC Converter

DC-DC converters are used to match the right input voltage which is required for DC to AC inverter section which drives the motor. The li-ion cells have full charge terminal voltage of 4.2V and full discharge voltage is 3.0V for safe operation. If a li-ion cell is charged above 4.2V, it may get over heated and get damaged. Similarly, if they are discharged below 3.0V, they may not charge up next time.

So, the DC-DC converter takes input from battery bank and maintains its output to a fix voltage during this variation of cell voltage and the respective battery bank. This gives regulated DC input supply to inverter section during complete battery discharge cycle.

This converter is bi-directional by design. When operating in one direction it takes input from battery bank and feeds to inverter circuit. When the breaks are applied on vehicle, the regenerative effect from asynchronous motor is fed back to inverter and then to DC DC converter, which then charges the battery again for a short while from stored energy.

DC-AC Inverter

The high voltage DC supply received from DC-DC converter is fed to AC inverter section which produces high voltage AC supply to run the asynchronous motor. Motors are usually 3-phase type, hence the DC-AC inverter produces high voltage 3-phase AC supply.

Inverter section is also bi-directional as it has to send back the voltage generated by regenerative action of asynchronous motor during breaking, back to bi-directional DC-DC converter, which then charges the battery on the go. The inverter section is the main controller of EV which can change the speed of vehicle by changing speed and power of motor.

Speed of induction motor can be changed simply by changing the input frequency, maintaining its power. And to change the motor power, the input voltage/current should be changed. So, the inverter section has capability to change its output frequency as well as its output voltage/current.

Motor

To convert the electrical energy received from battery banks into mechanical energy, electric cars uses motors. For smaller vehicles DC motors are also used, but for electric cars, buses and trucks we use 3-phase induction motor due to its high efficiency and brush less operation. Other brushed motors need replacement of carbon brushes time to time as they worn out due to rotation of shaft.

Asynchronous inductions motors can be used as motor as well as generator when rotated mechanically. This gives the benefit of using the motor's regenerative feedback voltage for charging battery when break is applied on vehicle.

As mentioned above in inverter section, induction motors speed and power can be controlled just by changing output voltage and frequency, hence no mechanical gear box is required to change speed. So, by default your electric car is gear less and hence no clutch assembly is also required. We have only a break and an accelerator paddle to operate. This further reduces mechanical assembly and loss in them.

A major benefit of motor over conventional internal combustion (IC) engine is that motor directly create rotational energy from electric power source, but the IC engine converts the linear motion of piston into circular motion hence there is again some drop in efficiency. Also there is a limit of speed at which piston can move inside the cylinder.

Auxiliary DC-DC Converter

Though the motor runs at high voltage coming from battery and DC-DC converter, there are many other electrical parts inside a vehicle which needs lower voltage to operate i.e. 12VDC or 24VDC, example head lamps, blinkers, music system and other dashboard equipment. To run these low voltage equipment, an auxiliary DC-DC converter can be used in EV, which will not unnecessary put load on main DC-DC converter while the vehicle is not in movement. Because the main DC-DC converter takes high voltage as input and gives high voltage at output, the power components inside that gets heated hence need cooling mechanism. This auxiliary DC-DC converter avoids this requirement by working separately and powering low voltage equipment while the vehicle is stationary.

Auxiliary Battery

Some manufacturers may use auxiliary conventional lead acid battery to operate such low voltage equipment which we saw above, while the vehicle is stationary. This reduces unwanted use of main battery bank which is mainly designed to run the vehicle through motor. In such case auxiliary DC-DC converter may not be included in vehicle as its purpose is solved using this low voltage auxiliary battery.

0 Comments